Manufacture

Display Partners have an extensive established supply chain allowing us to make just about anything. From presicions CNC to complicated injection molding, fabricated steel to die-casting, chemical etching to laser engraving, electronics to metal injection molding, we have you covered.

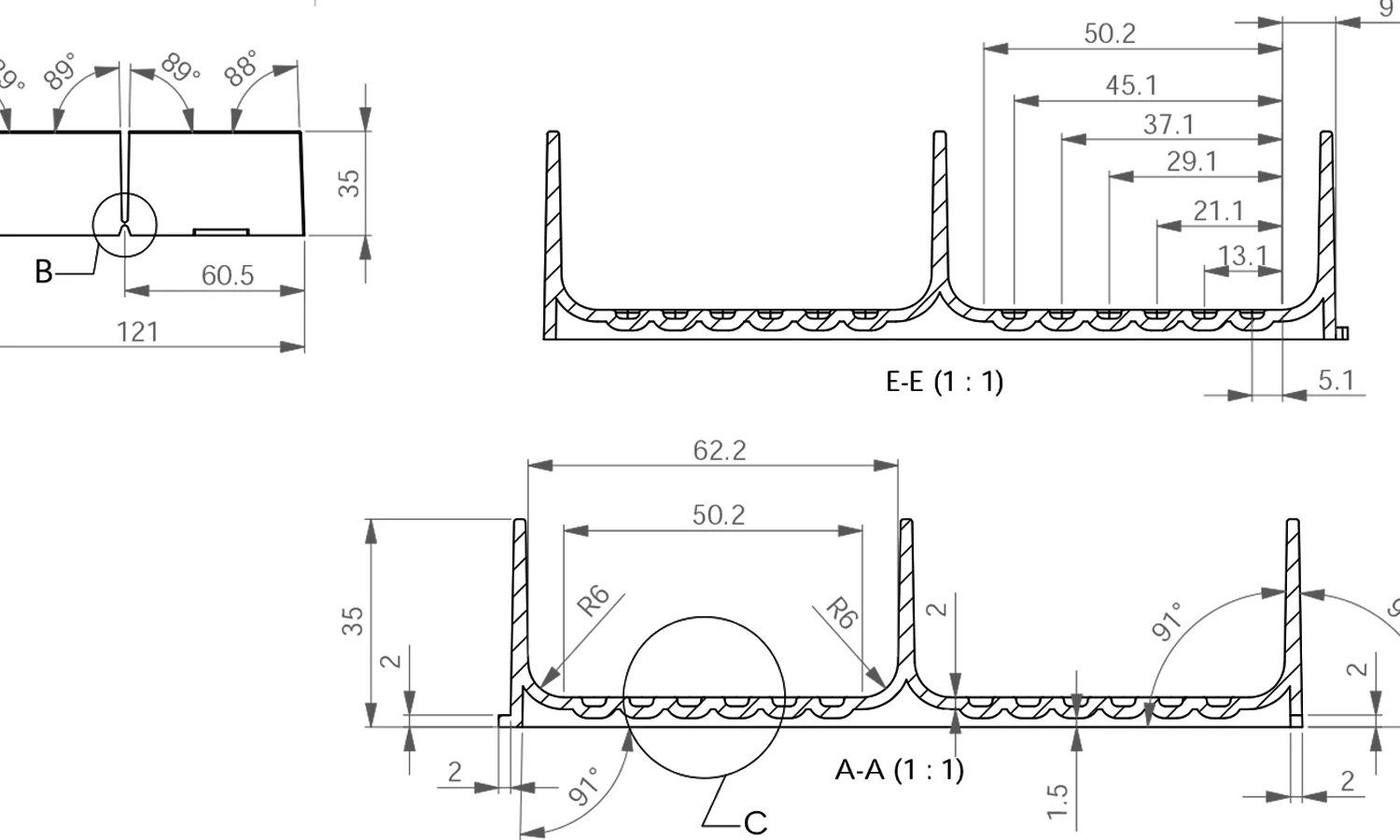

DFM

Design For Manufacture drawings are provided to our clients to ensure there is total visibility in the tooling process with the client.

It's important to make sure you are happy with parting lines, gate positions, ejector pin locations, draft angle analysis, thickness analysis, flow analysis, knit/weld line analysis, texturing/polishing confirmation, etc..

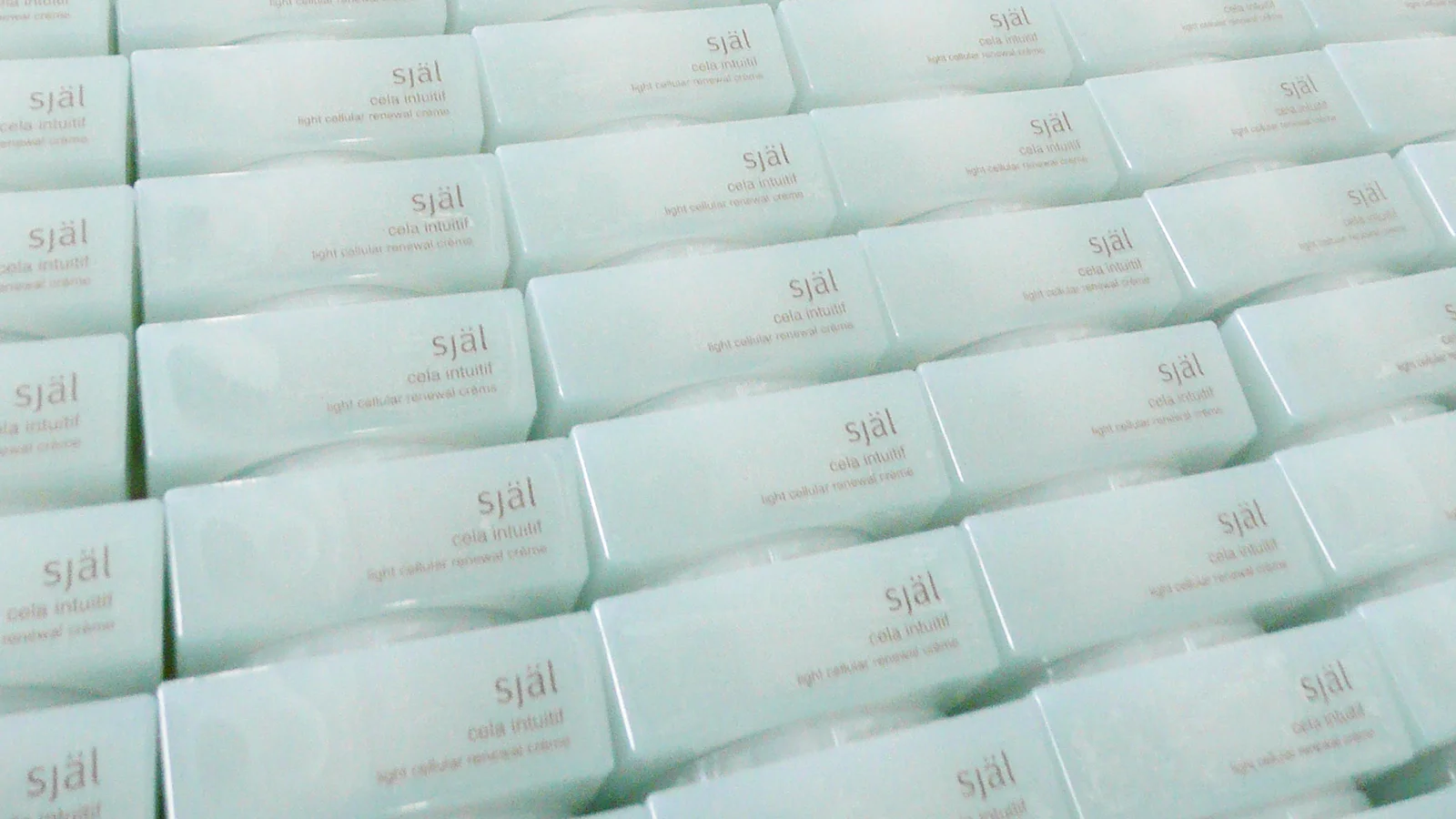

INJECTION MOLDING

Design For Manufacture drawings are provided to our clients to ensure there is total visibility in the tooling process with the client.

Whether you are looking for straight-shot simple tooling or something a little more complicated with sliding cams, removable cores, undercuts, hot-runner, date stamping, IML/IMD, Twin-shot, Triple-shot, Insert Molding...

TOOLING

Predictable quality and delivery

22 hour schedule

500 tools per month output.

6000 tools per year output.

Cell (equipment)

CNC, EDM, CMM

Standardization

Palletization

Inter-cell (process)

RFID tracking

Critical path analysis

Resource allocation

MIM

Metal Injection molding is a very useful process to create strong precision parts.

We are able to mold several steel (FeNialloy, 304L, 316L, 17-4ph ) along with other materials such as Kovar, Cu and Tungsten alloys.

Easily produce metal or ceramic parts with complex geometry shapes and structures.

Ability to cross-drill holes, radii, blind holes, internal features etc. with tight tolerances in one shot, with no secondary machining.

Many times MIM is a good alternative to CNC.

DIE CASTING

We work with cutting edge die-casting techniques producing premium parts for our clients.

Materials:

Zinc / Aluminum / Magnesium

Post Processing:

CNC machining, Shot blasting, Sand blasting, Barreling, Deburring & thermal deburring tapping

Decorative Finishes:

Electroplating Nickel / Tin / Chromium (Chrome) – Bright, Satin, and Black; Hex-Free Chromate Treatments; Painting; Anodizing; Wear Resistance; Passivating; Powder Coating Drilling; Tapping; Reaming.

CNC

We have extensive experience CNCing a range of materials including die casting, stainless steel, aluminium, zinc, alloys, speciality materials.

We use 3 axis, 5 axis & CNC lathes and can handle both small batch and high volume production.

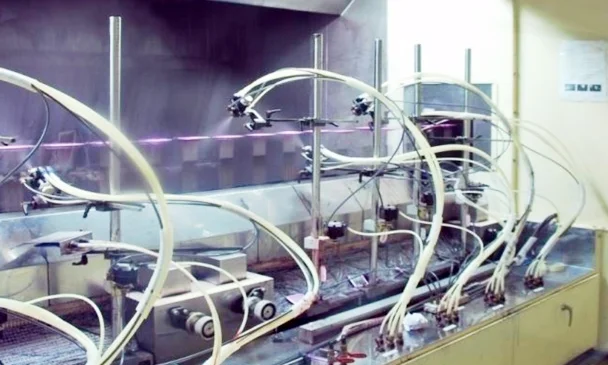

PAINTING

Temperature and humidity control clean room (10K class)

Japan Kawaguchi painting lines Fast, stable and predictable quality

On-site Japanese and local R&D lab ensures a quick color matching turnaround.

300 staff two shifts

Technician average 6+ yrs experience

Annual output 138M units

ANODIZING

Electroplating is an electrolytic process, in which metals are mostly separated from metal salt solutions with the use of a power source and chemical aids.

Anodizing is the electrolytic formation of an oxide layer on light alloys such as Aluminium and Magnesium. Both are electro-chemical processes for the refinement of base materials (e.g. nickel-plating, chrome-plating, gold-plating, anodizing, etc.).

Surface properties such as corrosion protection, appearance, electrical properties, resistance to wear, smoothness, ability to be soldered etc. can be significantly altered by applying thin metal layers.

ELECTRONICS

Complex PCB assemblies (PCBA)

Chip on board (COB) – Bonding

Surface Mount Technology (SMT)

Ball Grid Array (BGA) SMT

Flexible Printed Circuit (FPC)

Through Hole Insertion

Solder Paste Inspection Machine

Lead-Free Re-Flow Oven

Automatic Optical Inspection

Automatic Screen Printing Machine

Chip Placer

MFi 6.1 manufacturing

METAL STAMPING

Whether it’s a complex metal stamping requirement, rapid prototyping need or a conceptual design idea on products, Production Partners have the ability to meet your requirements.

Precision progressive stamping

Deep Draw parts

16T - 250T Presses

100M parts per month capacity

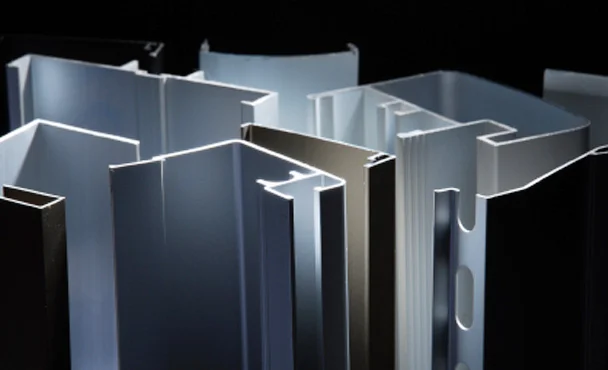

ALUMINUM EXTRUSION

When aluminum that is to be used as an extrusion is combined with a predetermined mixture of one or more elements, it is called an aluminium profile alloy. Its end-product performance is determined by both the alloy composition and the method of production. The production method, in turn, strongly influences the final temper of the alloys. Temper is the combination of hardness and strength imparted to a metal by mechanical or thermal treatments. The temper designation is characterized by its metallurgical structures and mechanical properties.

Aluminium alloys 6063, 6082, ,6061, 6463 polish, 6060, 6106, 6005, 6005A, 6061, 6262, 7005, 7075, 4032, 2011, 1100 - others available on request and conditions.

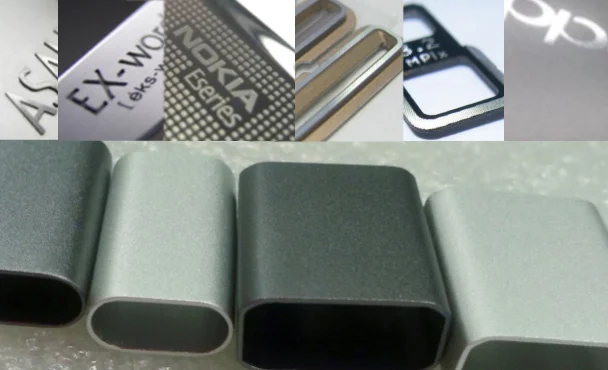

METAL FINISHING

We can provide a range of specialty coatings and finishes to your parts.

Ink Filled

Screen Printing

Diamond Cutting

Laser Marking

PVD

Chemical Etching

Dual Texture

Anodizing

Polishing

Sandblasting

Brushing

Multi-processing